Steel Cribbage Board Template

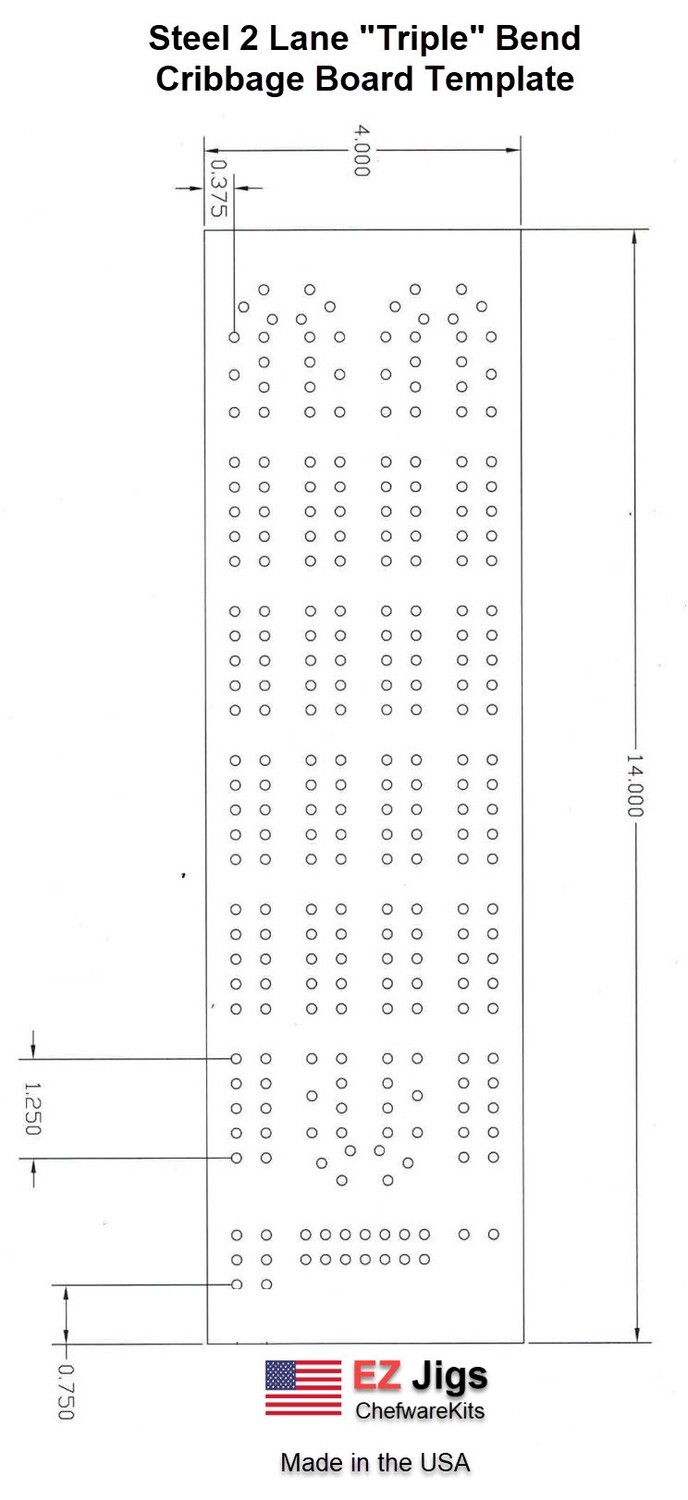

Steel Cribbage Board Template - Then i'll trace that on the wood, flip it to other side, trace it there, and voila, you've got a plaque! Any help would be greatly appreciated. A shop made wood screen door from a good door shop will fall apart in a short time. Oh, and light coats of wipe on poly might be good for finishing without plugging up the holes. I'm making a cribbage board for my dad and i'm not sure what to use for a finish. The blade hit a knot, and the knot shot straight up, i proceeded to shut the saw and my dust collection and inspect what just happen. The other day i was ripping some 2x12's down to 4 and mid cut on my second cut of one board. I dunno how you'd fix it unless you just did some inlays on the track. A steel template is durable (made of 10 gauge steel) which will last a very very long time, unlike plastic templates. Its a beautiful piece of walnut and it has an edge of bark still on it. To get it perfectly identical on both sides, i draw and cut out half of it on poster board. I'm sure some of the other craftsman will chime in and recommend other saws. They have door shapers to make perfect joints and all the other equipment. A cribbage board template is designed to make it easy to produce straight lines with perfectly spaced holes. 4”side flat on the table. Lets say you have a 2x4 that you want to rip into 1/16 strips. I dunno how you'd fix it unless you just did some inlays on the track. If it would help, i can post a picture of the piece of walnut im working with. A steel template is durable (made of 10 gauge steel) which will last a very very long time, unlike plastic templates. Oh, and light coats of wipe on poly might be good for finishing without plugging up the holes. 4”side flat on the table. Manufacturers would have special tooling made, probably for an overarm router in this case. Any help would be greatly appreciated. A steel template is durable (made of 10 gauge steel) which will last a very very long time, unlike plastic templates. The end result will be a high quality professional product why a steel template? Oh, and light coats of wipe on poly might be good for finishing without plugging up the holes. Its a beautiful piece of walnut and it has an edge of bark still on it. I have no idea what i should use for a finish!!! I've been thinking about making a few cribbage boards lately. Job site type saws are. I'm sure some of the other craftsman will chime in and recommend other saws. Any help would be greatly appreciated. The blade hit a knot, and the knot shot straight up, i proceeded to shut the saw and my dust collection and inspect what just happen. If it would help, i can post a picture of the piece of walnut. A shop made wood screen door from a good door shop will fall apart in a short time. I'm sure some of the other craftsman will chime in and recommend other saws. The other day i was ripping some 2x12's down to 4 and mid cut on my second cut of one board. To get it perfectly identical on both. I always just draw mine out. I have no idea what i should use for a finish!!! The other day i was ripping some 2x12's down to 4 and mid cut on my second cut of one board. A cribbage board template is designed to make it easy to produce straight lines with perfectly spaced holes. A shop made wood. Oh, and light coats of wipe on poly might be good for finishing without plugging up the holes. A cribbage board template is designed to make it easy to produce straight lines with perfectly spaced holes. The other day i was ripping some 2x12's down to 4 and mid cut on my second cut of one board. 4”side flat on. I'm making a cribbage board for my dad and i'm not sure what to use for a finish. Manufacturers would have special tooling made, probably for an overarm router in this case. 4”side flat on the table. Job site type saws are really are good for shorter boards like 8 ft or less and they don't care if they're all. Any help would be greatly appreciated. Manufacturers would have special tooling made, probably for an overarm router in this case. Why use a cribbage board template? You may be able to set up a template, template guide on the router and use a keyhole bit. Its a beautiful piece of walnut and it has an edge of bark still on. Not knowing what the spread is for the peg holes i'd suggest you make an index jig for the drill press, make a template from it and use it as an overlay on the cribbage board. Lets say you have a 2x4 that you want to rip into 1/16 strips. They have door shapers to make perfect joints and all. I'm sure some of the other craftsman will chime in and recommend other saws. My first thought was “wow another cool jig” i get it for repeatability. 4”side flat on the table. A steel template is durable (made of 10 gauge steel) which will last a very very long time, unlike plastic templates. Job site type saws are really are. Not knowing what the spread is for the peg holes i'd suggest you make an index jig for the drill press, make a template from it and use it as an overlay on the cribbage board. Lets say you have a 2x4 that you want to rip into 1/16 strips. Why use a cribbage board template? My first thought was “wow another cool jig” i get it for repeatability. That is why you never see them anymore. A steel template is durable (made of 10 gauge steel) which will last a very very long time, unlike plastic templates. If it would help, i can post a picture of the piece of walnut im working with. I've been thinking about making a few cribbage boards lately. A straight bit the same diameter as the keyhole narrow cut could be used with the same template to cut the recess with a plunge router. I'm sure some of the other craftsman will chime in and recommend other saws. Then i'll trace that on the wood, flip it to other side, trace it there, and voila, you've got a plaque! Oh, and light coats of wipe on poly might be good for finishing without plugging up the holes. They have door shapers to make perfect joints and all the other equipment. 4”side flat on the table. A cribbage board template is designed to make it easy to produce straight lines with perfectly spaced holes. The other day i was ripping some 2x12's down to 4 and mid cut on my second cut of one board.Printable Cribbage Board Templates

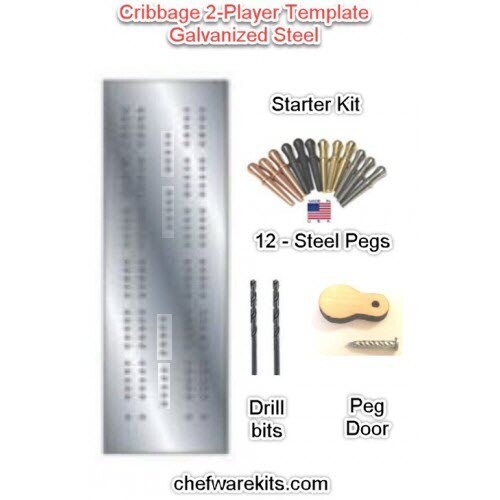

Cribbage Board 2lane Steel Template (Woodworking Kit) Made in the USA

Cribbage Board Template PDF WoodWorking Projects & Plans

Cribbage Board Templates Metal Printable Word Searches

Cribbage Board Extra Large 4 Player Steel Template Made in the USA

Cribbage Board 2lane Steel Template (Woodworking Kit)

Rockler Cribbage Board Templates

Cribbage Board 2lane Steel Template Starter Kit (Woodworking Kit) Made

Cribbage Board Circle 10in Diameter Round 4 Player Steel Template

Cribbage Board Steel Template 3 Pack (3lane, 2lane, 4lane) Made in

To Get It Perfectly Identical On Both Sides, I Draw And Cut Out Half Of It On Poster Board.

Drawing A Centerline Helps When Laying It Out.

Its A Beautiful Piece Of Walnut And It Has An Edge Of Bark Still On It.

The End Result Will Be A High Quality Professional Product Why A Steel Template?

Related Post: