Scar Template

Scar Template - For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. Mec sqe will fill in the product defect(s) in a “s/b” and “is” format. Streamline supplier management with our supplier corrective action request (scar) template. Efficiently track, document, and resolve corrective actions. Ensure that the root cause reaches sufficient depth in the causal chain. A scar is a document that lists issues/defects on a product delivered by a supplier and request… Bcia 8572, suspected child abuse report Scar analysis reports are considered confidential and proprietary to idirect. The requested method (car or 8d) shall be followed from supplier (and is. Describe the issue that is causing the parts or process to fail, from the customer’s point of view. The following lists a useful set of guidelines to assist completing a supplier corrective action response for nonconformity reports (scars). Bcia 8572, suspected child abuse report author: Mec sqe will fill in the product defect(s) in a “s/b” and “is” format. A scar is a document that lists issues/defects on a product delivered by a supplier and request… The requested method (car or 8d) shall be followed from supplier (and is. California department of justice, bcia, caci expedite subject: Up to 40% cash back the supplier corrective action report (scar) is a document that lists issues/defects that have been found on a product delivered by a supplier, communicates them. The document appears to be a supplier corrective action request. Efficiently track, document, and resolve corrective actions. Root cause analysis methodology should be used for effective problem solving. Scar analysis reports are considered confidential and proprietary to idirect. Supplier corrective action request (scar) response process the intent of this document is to provide lm aero supply base with guidance on how to submit scar responses using the. The document appears to be a supplier corrective action request. Download and edit our scar process model powerpoint template for discussing. Root cause analysis methodology should be used for effective problem solving. Describe the issue that is causing the parts or process to fail, from the customer’s point of view. Up to 40% cash back the supplier corrective action report (scar) is a document that lists issues/defects that have been found on a product delivered by a supplier, communicates them. Ensure. Describe the issue that is causing the parts or process to fail, from the customer’s point of view. Ensure that the root cause reaches sufficient depth in the causal chain. Bcia 8572, suspected child abuse report Bcia 8572, suspected child abuse report author: Learn what a scar is, how to manage it, and what it contains. The following lists a useful set of guidelines to assist completing a supplier corrective action response for nonconformity reports (scars). Efficiently track, document, and resolve corrective actions. Creation strongly urges the supplier use the global 8d. For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. Download and edit our scar process. Bcia 8572, suspected child abuse report Root cause analysis methodology should be used for effective problem solving. Our standard is the global 8d scar format. Enter name and contact details for individual who performed the scar investigation. Download and edit our scar process model powerpoint template for discussing the phases of scar requesting framework. Download and edit our scar process model powerpoint template for discussing the phases of scar requesting framework. Root cause analysis methodology should be used for effective problem solving. For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. Bcia 8572, suspected child abuse report Supplier corrective action request (scar) response process the. The document appears to be a supplier corrective action request. For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. Describe the issue that is causing the parts or process to fail, from the customer’s point of view. The blank 8d scar template is available on the supplier website. California department of. Root cause analysis methodology should be used for effective problem solving. California department of justice, bcia, caci expedite subject: Efficiently track, document, and resolve corrective actions. Scar analysis reports are considered confidential and proprietary to idirect. Ensure that the root cause reaches sufficient depth in the causal chain. Mec sqe will fill in the product defect(s) in a “s/b” and “is” format. For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. California department of justice, bcia, caci expedite subject: Supplier corrective action request (scar) response process the intent of this document is to provide lm aero supply base with. California department of justice, bcia, caci expedite subject: Learn what a scar is, how to manage it, and what it contains. Up to 40% cash back the supplier corrective action report (scar) is a document that lists issues/defects that have been found on a product delivered by a supplier, communicates them. Our standard is the global 8d scar format. The. Scar analysis reports are considered confidential and proprietary to idirect. For internal mec reference purposes, this section may also include the inspector’s name, day of inspection, and internal. The requested method (car or 8d) shall be followed from supplier (and is. Streamline supplier management with our supplier corrective action request (scar) template. Efficiently track, document, and resolve corrective actions. The document appears to be a supplier corrective action request. Download and edit our scar process model powerpoint template for discussing the phases of scar requesting framework. Describe the issue that is causing the parts or process to fail, from the customer’s point of view. The following lists a useful set of guidelines to assist completing a supplier corrective action response for nonconformity reports (scars). Root cause analysis methodology should be used for effective problem solving. Learn what a scar is, how to manage it, and what it contains. Mec sqe will fill in the product defect(s) in a “s/b” and “is” format. Bcia 8572, suspected child abuse report California department of justice, bcia, caci expedite subject: Up to 40% cash back the supplier corrective action report (scar) is a document that lists issues/defects that have been found on a product delivered by a supplier, communicates them. Ensure that the root cause reaches sufficient depth in the causal chain.Scar Template

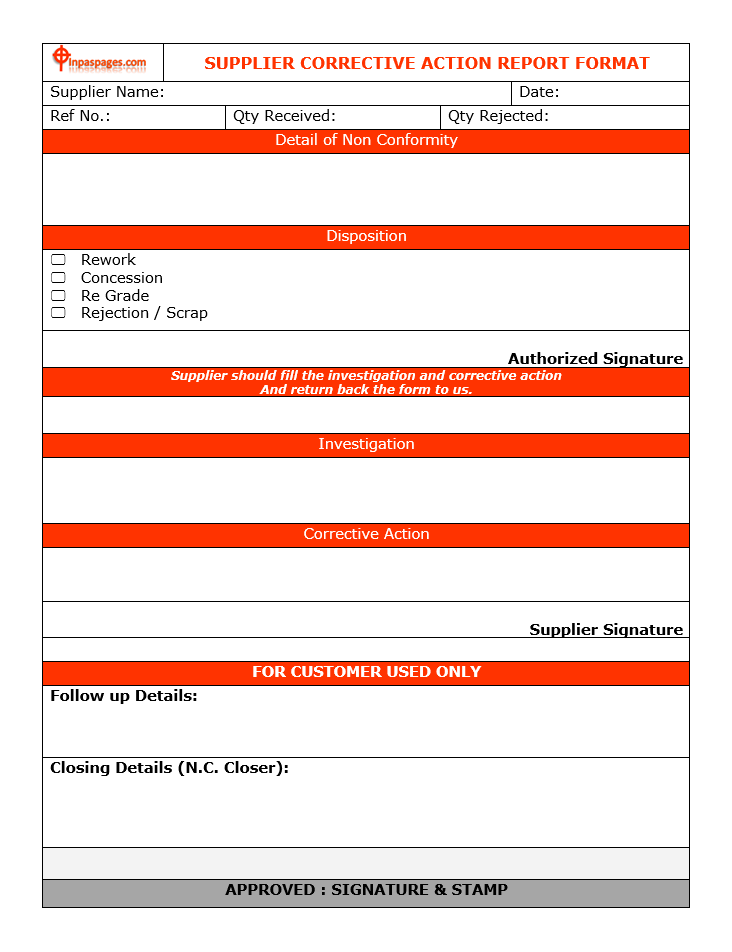

Corrective Action Report Template

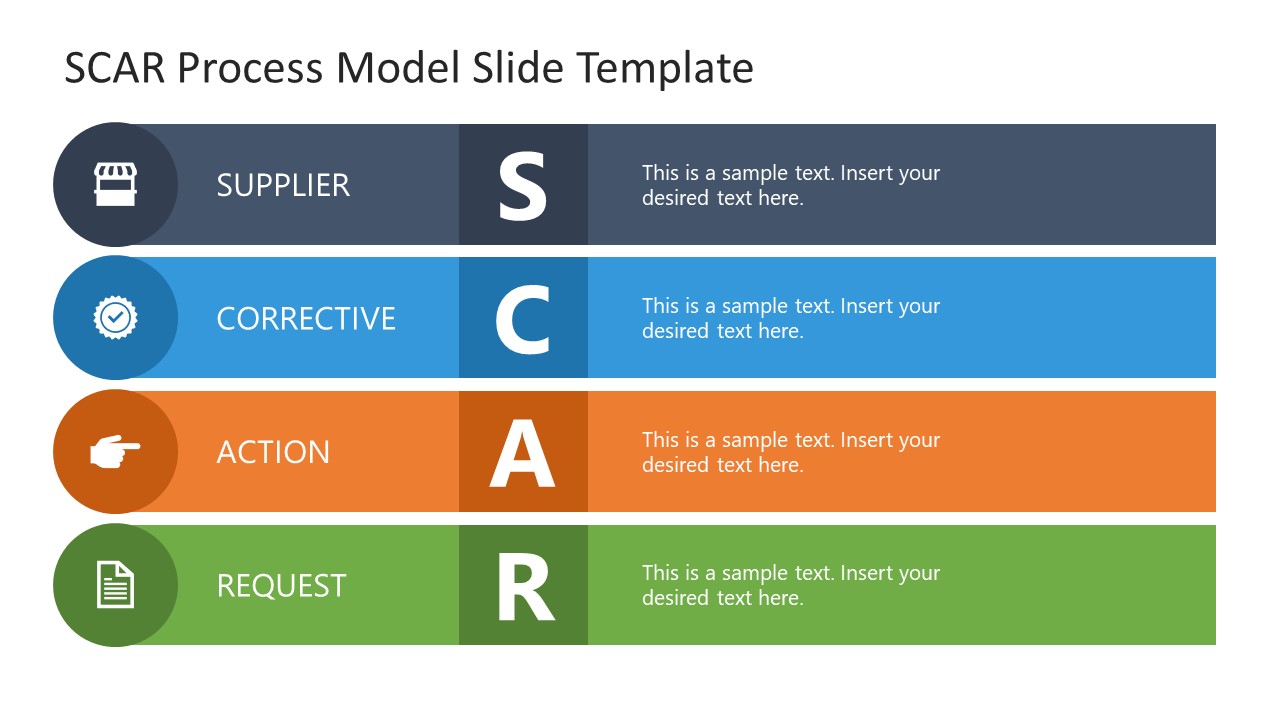

SCAR Process Model PowerPoint Template

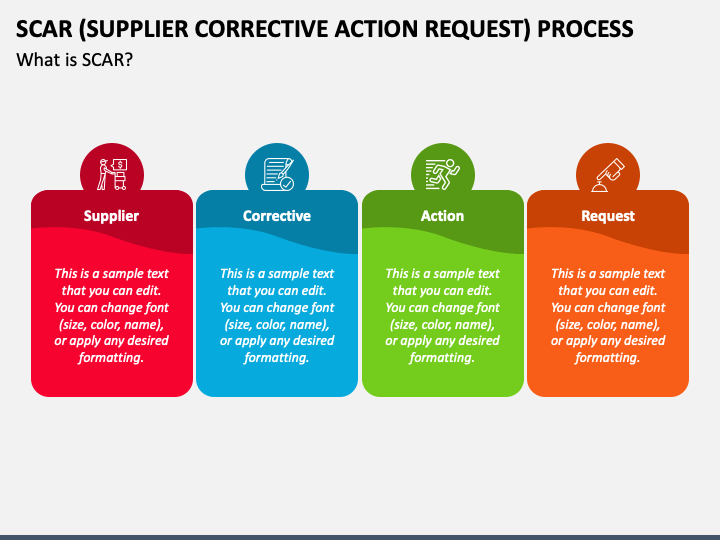

The extraordinary Scar (Supplier Corrective Action Report) Capa

Scars Template

Supplier corrective action report SCAR

Harry Potter Pin The Scar Printable

SCAR (Supplier Corrective Action Request) Process PowerPoint and Google

Scar Template

Corrective Action Report Template (5) PROFESSIONAL TEMPLATES Report

Our Standard Is The Global 8D Scar Format.

A Scar Is A Document That Lists Issues/Defects On A Product Delivered By A Supplier And Request…

Bcia 8572, Suspected Child Abuse Report Author:

Enter Name And Contact Details For Individual Who Performed The Scar Investigation.

Related Post: