Root Cause And Corrective Action Template

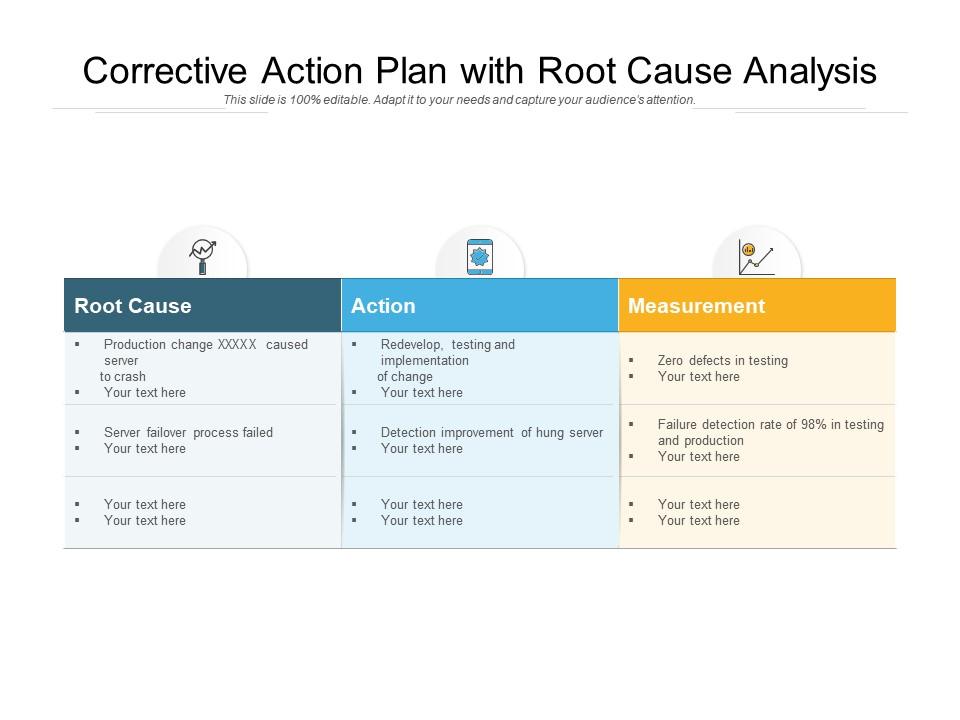

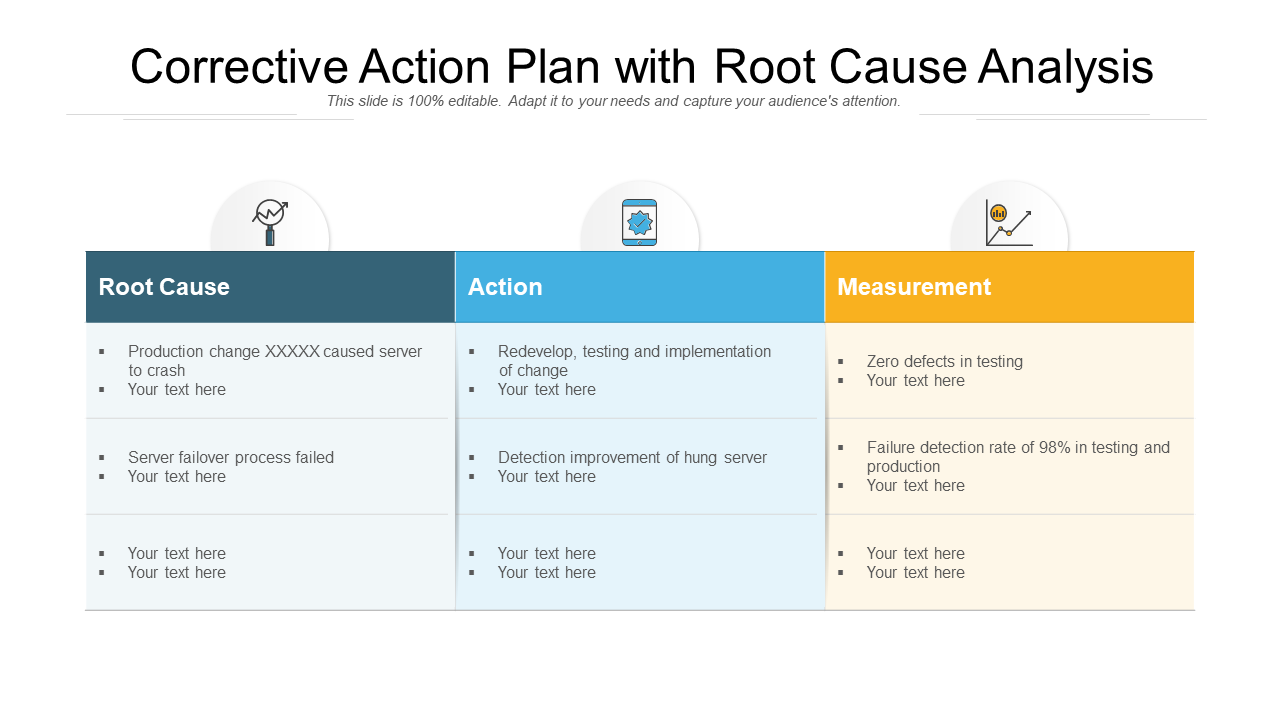

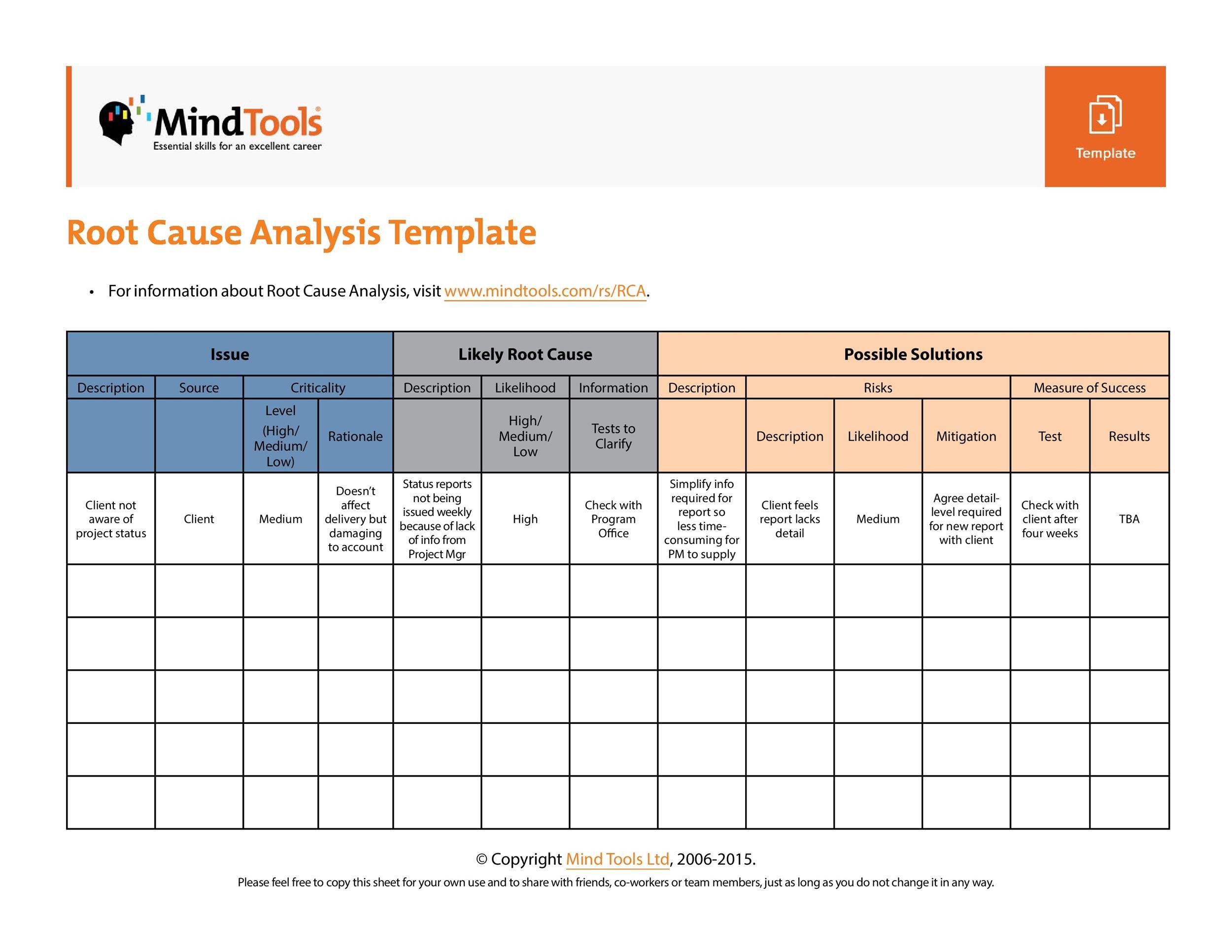

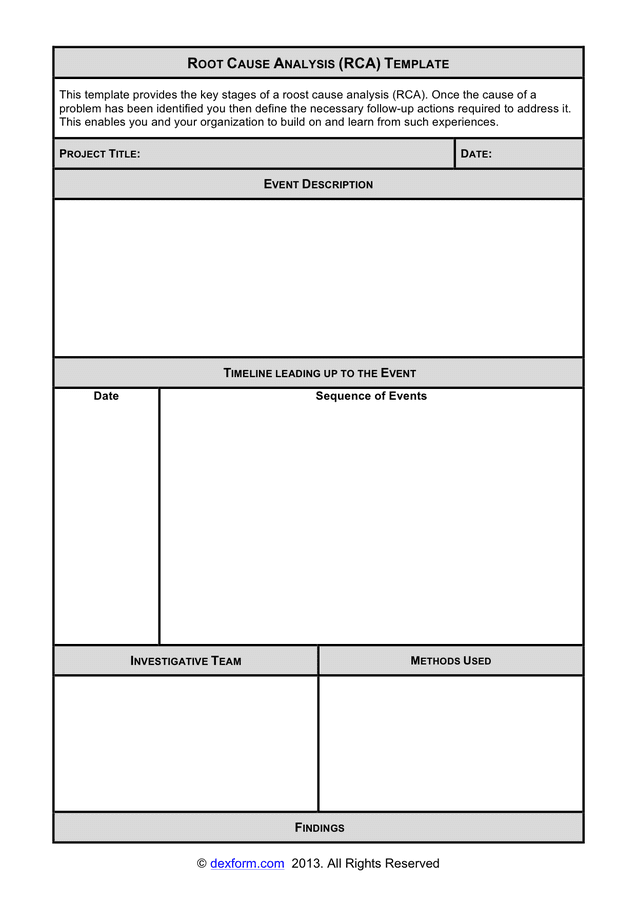

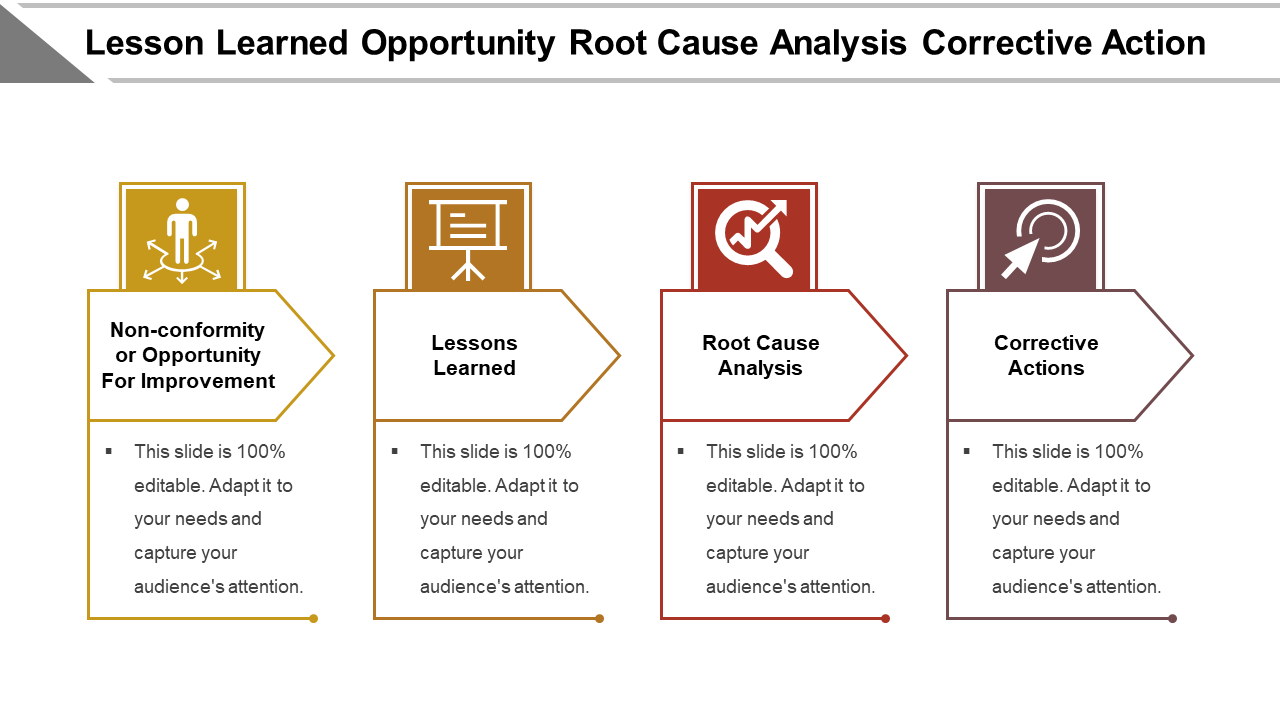

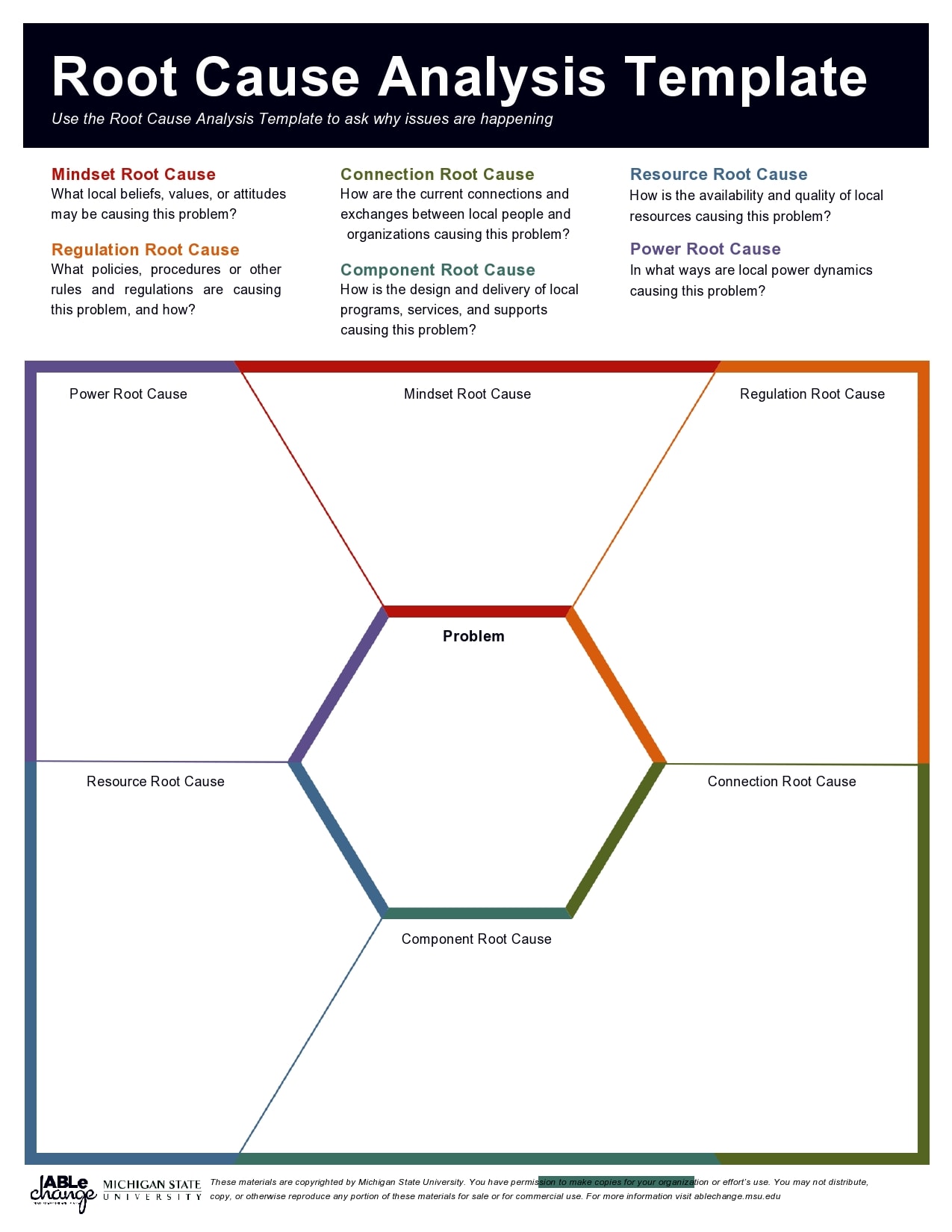

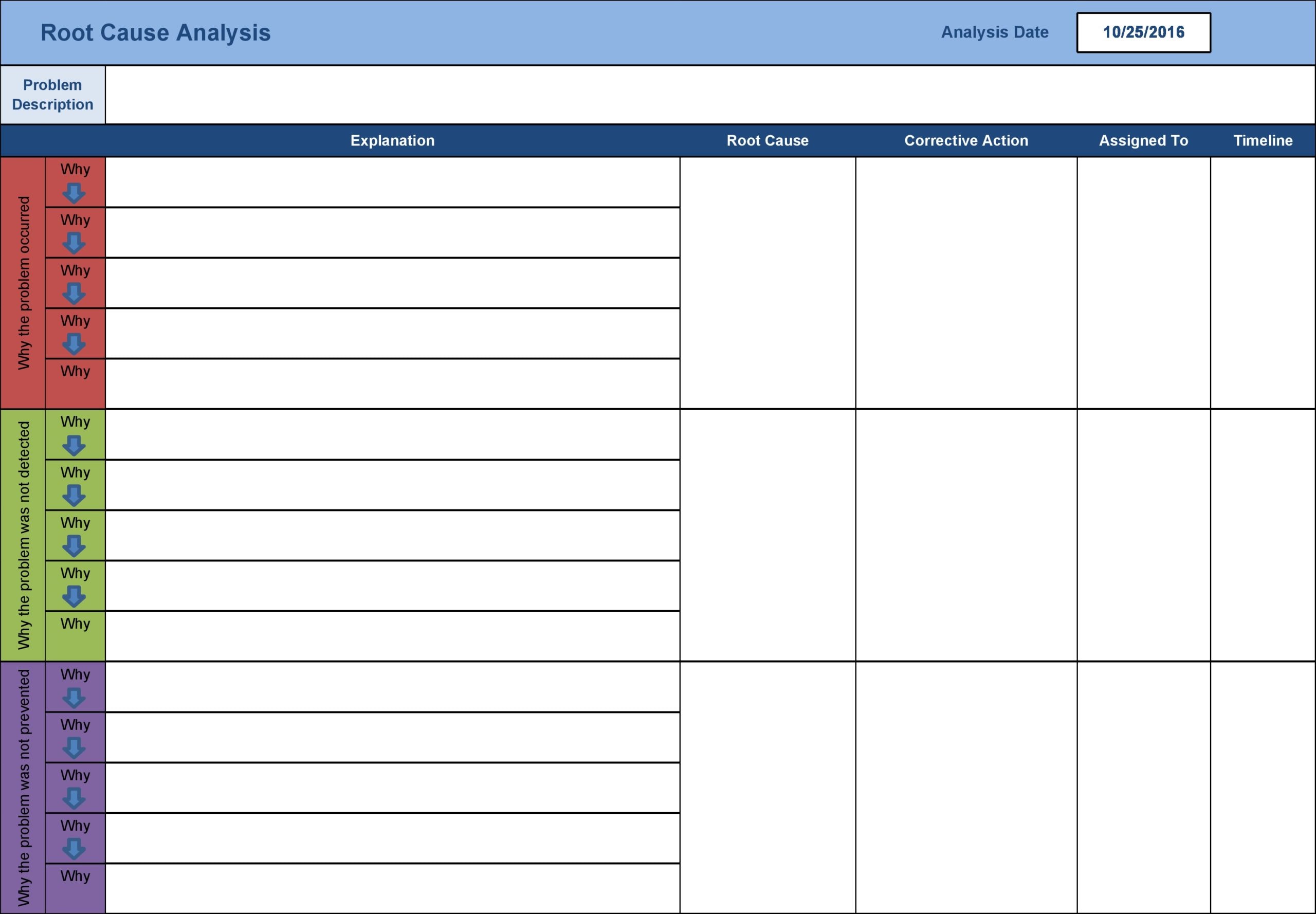

Root Cause And Corrective Action Template - If the final why has no controllable solution, return to the previous why. root cause. Define the problem corrective action to take. 5 why’s template define the. Explosion at acme chemical company mark berry, laboratory manager; It includes a problem statement, action steps, a timeline, and a desired outcome. Corrective actions are often used in hr and other manufacturing contexts, but other industries. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. The event describe what happened and any harm that resulted. 5 whys root cause analysis template. D4 identify the root cause list all possible root causes for the problems. Capa, or corrective action and preventive action, can provide a structure for finding the root cause of problems, solving those problems, documenting the conditions and solutions for the future, and looking for potential problems and their solutions. Corrective actions are often used in hr and other manufacturing contexts, but other industries. D4 identify the root cause list all possible root causes for the problems. 5 why’s template define the. Why is this a problem? 5 whys root cause analysis template. It includes steps to describe the problem, determine its causes, and implement solutions to prevent recurrence. Define the problem step 2: Product/process department completed by date. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date action to begin date to. Identify the proximate cause, if known. 5 why’s template define the. Product/process department completed by date. It includes a problem statement, action steps, a timeline, and a desired outcome. The event describe what happened and any harm that resulted. Primary cause why is it happening? Use root cause analysis techniques such as five whys to identify these. Corrective actions are often used in hr and other manufacturing contexts, but other industries. Bob graphy, company safety officer; Rick james, r&d officer 1. The event describe what happened and any harm that resulted. Define the problem corrective action to take. The corrective action process helps you create, implement, and verify a corrective action plan. Explosion at acme chemical company mark berry, laboratory manager; 5 why’s template define the. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. Why is this a problem? D4 identify the root cause list all possible root causes for the problems. It includes a problem statement, action steps, a timeline, and a desired. If the final why has no controllable solution, return to the previous why. root cause. Define the problem corrective action to take. Identify the proximate cause, if known. Explosion at acme chemical company mark berry, laboratory manager; Define the problem step 2: Capa, or corrective action and preventive action, can provide a structure for finding the root cause of problems, solving those problems, documenting the conditions and solutions for the future, and looking for potential problems and their solutions. Define the problem corrective action to take. Product/process department completed by date. Identify the proximate cause, if known. This cause mapping template combines. Define the problem step 2: It includes steps to describe the problem, determine its causes, and implement solutions to prevent recurrence. 5 whys root cause analysis template. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date action to begin date to. Bob graphy, company safety officer; Root cause analysis report example: Capa, or corrective action and preventive action, can provide a structure for finding the root cause of problems, solving those problems, documenting the conditions and solutions for the future, and looking for potential problems and their solutions. Bob graphy, company safety officer; Corrective actions are often used in hr and other manufacturing contexts, but other. Why is this a problem? It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Rick james, r&d officer 1. The corrective action process helps you create, implement, and verify a corrective action plan. Explosion at acme chemical company mark berry, laboratory manager; If the final why has no controllable solution, return to the previous why. root cause. Identify the proximate cause, if known. Capa, or corrective action and preventive action, can provide a structure for finding the root cause of problems, solving those problems, documenting the conditions and solutions for the future, and looking for potential problems and their solutions. Bob graphy,. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Explosion at acme chemical company mark berry, laboratory manager; Identify the proximate cause, if known. Define the problem corrective action to take. Product/process department completed by date. Bob graphy, company safety officer; 5 whys root cause analysis template. Use root cause analysis techniques such as five whys to identify these. Rick james, r&d officer 1. The corrective action process helps you create, implement, and verify a corrective action plan. This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. Root cause analysis report example: It includes a problem statement, action steps, a timeline, and a desired outcome. If the final why has no controllable solution, return to the previous why. root cause. Corrective actions are often used in hr and other manufacturing contexts, but other industries. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date action to begin date to.Root Cause Corrective Action Template

Corrective Action And Root Cause Analysis Printable Templates Free

Root Cause Corrective Action Template

Top 20 Root Cause Analysis Templates to Limit Your Business Problems

40+ Effective Root Cause Analysis Templates, Forms & Examples

NCR Root Cause And Corrective Action Audit Internal Audit For Root

Root cause analysis template in Word and Pdf formats

Top 20 Root Cause Analysis Templates to Limit Your Business Problems

30 Simple Root Cause Analysis Templates (+Examples)

30 Simple Root Cause Analysis Templates (+Examples)

Primary Cause Why Is It Happening?

It Includes Steps To Describe The Problem, Determine Its Causes, And Implement Solutions To Prevent Recurrence.

Define The Problem Step 2:

Capa, Or Corrective Action And Preventive Action, Can Provide A Structure For Finding The Root Cause Of Problems, Solving Those Problems, Documenting The Conditions And Solutions For The Future, And Looking For Potential Problems And Their Solutions.

Related Post: