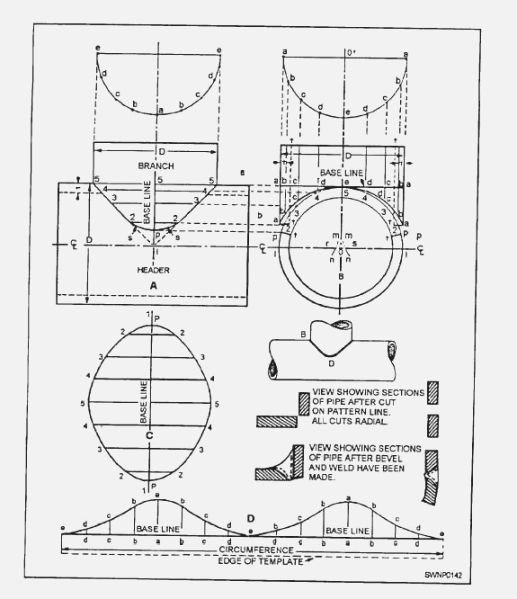

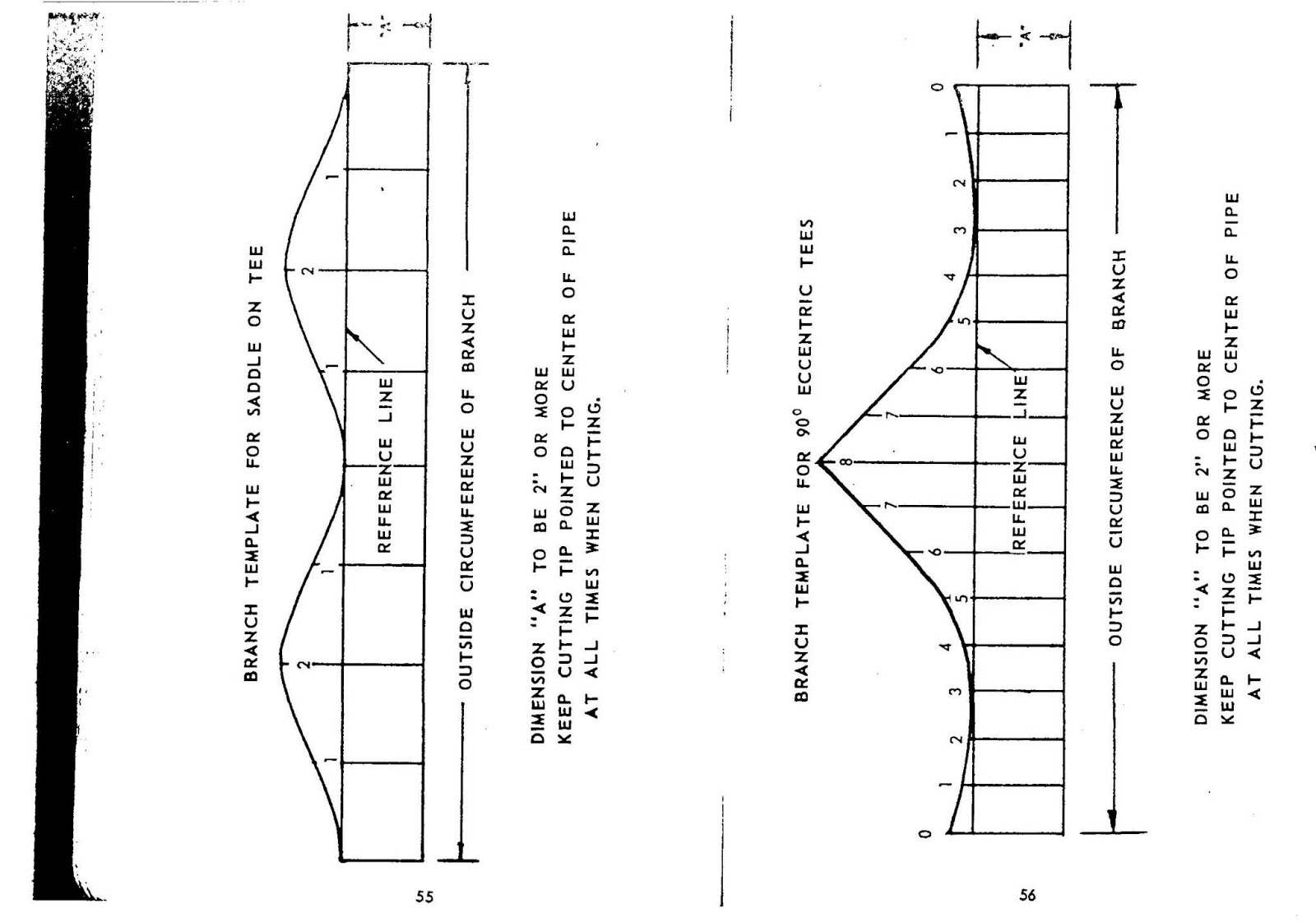

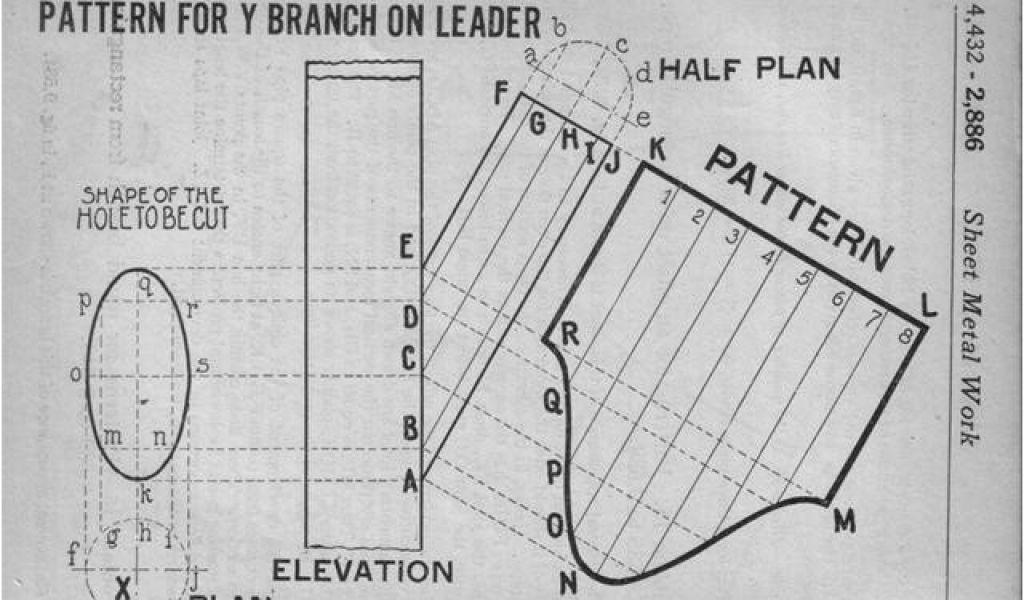

Pipe Saddle Template

Pipe Saddle Template - It would have probably have been better to use 3/4 pipe for the main trunk line and 1/2. All npt threads is 1⁄16 per inch (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. Any way i built a pipe plate out of a 10 piece of 3 channel. You can get sockets with a double square, we have a 5/16 one pressed onto a tee holder which fits the toolpost, saddle locks, saddle stops, compound swivel and the locking. Pipe threads are tapered, and for larger sizes, it is a good idea to use a tapered reamer to size the hole before tapping. The angle between the taper and the center axis. As far as piping for air, i just finished plumbing my machine shop with 1/2 black pipe. He is running some 4 threaded steam pipe. I welded a 1/2 plate on top of the channel and secured the pipe plate to the pole with two 1.5 ratchet straps. This has 4 holes that feed the lines. He is wondering if the threaded joints should be welded after assembly so the joints are well sealed. Next idea i had was to purchase a coupling nut that fits inside the pipe and then drill both the pipe and the sides of the nut for some screws to secure it in the end of the pipe. Ditto on checking for proper tap size, 9/16 for 3/8 pipe thread. As far as piping for air, i just finished plumbing my machine shop with 1/2 black pipe. It would have probably have been better to use 3/4 pipe for the main trunk line and 1/2. Only one of these goes to what i am calling a pump. All npt threads is 1⁄16 per inch (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. While it is not as important with smaller pipe taps, a reamer will make tapping easier. There is a shallower part to press the flattened part of the pipe, and a deeper portion to allow for the pipe to spread out as it transitions to the squashed part. Pipe threads are tapered, and for larger sizes, it is a good idea to use a tapered reamer to size the hole before tapping. He is wondering if the threaded joints should be welded after assembly so the joints are well sealed. Ditto on checking for proper tap size, 9/16 for 3/8 pipe thread. On the front of the saddle there is a cavity that holds about a 1/3 cup of oil. I don't know if one is available for 1/8. There is a. Ditto on checking for proper tap size, 9/16 for 3/8 pipe thread. I told him i never heard of welding. I don't know if one is available for 1/8. There is a shallower part to press the flattened part of the pipe, and a deeper portion to allow for the pipe to spread out as it transitions to the squashed. As far as piping for air, i just finished plumbing my machine shop with 1/2 black pipe. You can get sockets with a double square, we have a 5/16 one pressed onto a tee holder which fits the toolpost, saddle locks, saddle stops, compound swivel and the locking. I told him i never heard of welding. While it is not. He is running some 4 threaded steam pipe. There is a shallower part to press the flattened part of the pipe, and a deeper portion to allow for the pipe to spread out as it transitions to the squashed part. Ditto on checking for proper tap size, 9/16 for 3/8 pipe thread. Only one of these goes to what i. You can get sockets with a double square, we have a 5/16 one pressed onto a tee holder which fits the toolpost, saddle locks, saddle stops, compound swivel and the locking. I told him i never heard of welding. It would have probably have been better to use 3/4 pipe for the main trunk line and 1/2. The angle between. He is wondering if the threaded joints should be welded after assembly so the joints are well sealed. Any way i built a pipe plate out of a 10 piece of 3 channel. It would have probably have been better to use 3/4 pipe for the main trunk line and 1/2. I don't know if one is available for 1/8.. On the front of the saddle there is a cavity that holds about a 1/3 cup of oil. I don't know if one is available for 1/8. This has 4 holes that feed the lines. All npt threads is 1⁄16 per inch (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. It would. Any way i built a pipe plate out of a 10 piece of 3 channel. Next idea i had was to purchase a coupling nut that fits inside the pipe and then drill both the pipe and the sides of the nut for some screws to secure it in the end of the pipe. Ditto on checking for proper tap. I don't know if one is available for 1/8. On the front of the saddle there is a cavity that holds about a 1/3 cup of oil. You can get sockets with a double square, we have a 5/16 one pressed onto a tee holder which fits the toolpost, saddle locks, saddle stops, compound swivel and the locking. Next idea. Any way i built a pipe plate out of a 10 piece of 3 channel. There is a shallower part to press the flattened part of the pipe, and a deeper portion to allow for the pipe to spread out as it transitions to the squashed part. He is wondering if the threaded joints should be welded after assembly so. Pipe threads are tapered, and for larger sizes, it is a good idea to use a tapered reamer to size the hole before tapping. He is wondering if the threaded joints should be welded after assembly so the joints are well sealed. Only one of these goes to what i am calling a pump. He is running some 4 threaded steam pipe. It would have probably have been better to use 3/4 pipe for the main trunk line and 1/2. On the front of the saddle there is a cavity that holds about a 1/3 cup of oil. You can get sockets with a double square, we have a 5/16 one pressed onto a tee holder which fits the toolpost, saddle locks, saddle stops, compound swivel and the locking. I don't know if one is available for 1/8. There is a shallower part to press the flattened part of the pipe, and a deeper portion to allow for the pipe to spread out as it transitions to the squashed part. All npt threads is 1⁄16 per inch (3⁄4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. I told him i never heard of welding. While it is not as important with smaller pipe taps, a reamer will make tapping easier. This has 4 holes that feed the lines. Any way i built a pipe plate out of a 10 piece of 3 channel. The angle between the taper and the center axis.Printable Pipe Saddle Templates

Printable Pipe Saddle Templates

Free Printable Pipe Saddle Template Printable Templates Your GoTo

Printable Pipe Saddle Templates

Printable Pipe Saddle Templates

Wrap Around Printable Pipe Saddle Template Printable Templates Free

Printable Pipe Saddle Templates

27/8 Total Cut Pipe Guide Saddle TemplateTemplet 49947024 SCP47024

Pipe Saddle Template Printable Printable Templates

Printable Pipe Saddle Templates

I Welded A 1/2 Plate On Top Of The Channel And Secured The Pipe Plate To The Pole With Two 1.5 Ratchet Straps.

Next Idea I Had Was To Purchase A Coupling Nut That Fits Inside The Pipe And Then Drill Both The Pipe And The Sides Of The Nut For Some Screws To Secure It In The End Of The Pipe.

As Far As Piping For Air, I Just Finished Plumbing My Machine Shop With 1/2 Black Pipe.

Ditto On Checking For Proper Tap Size, 9/16 For 3/8 Pipe Thread.

Related Post: