Manufacturing Traveler Template

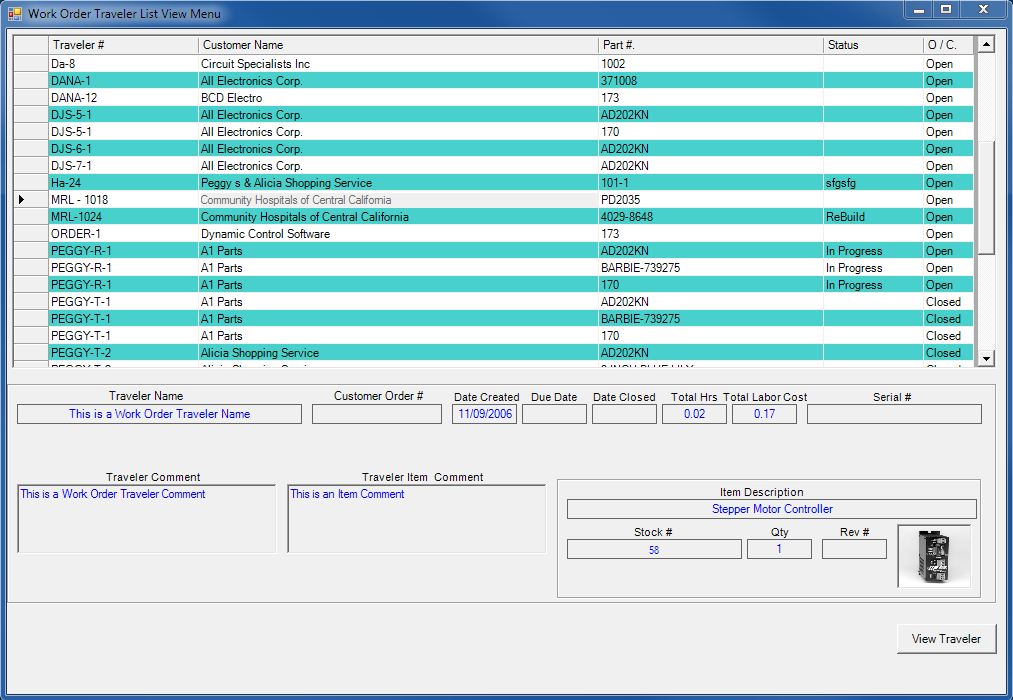

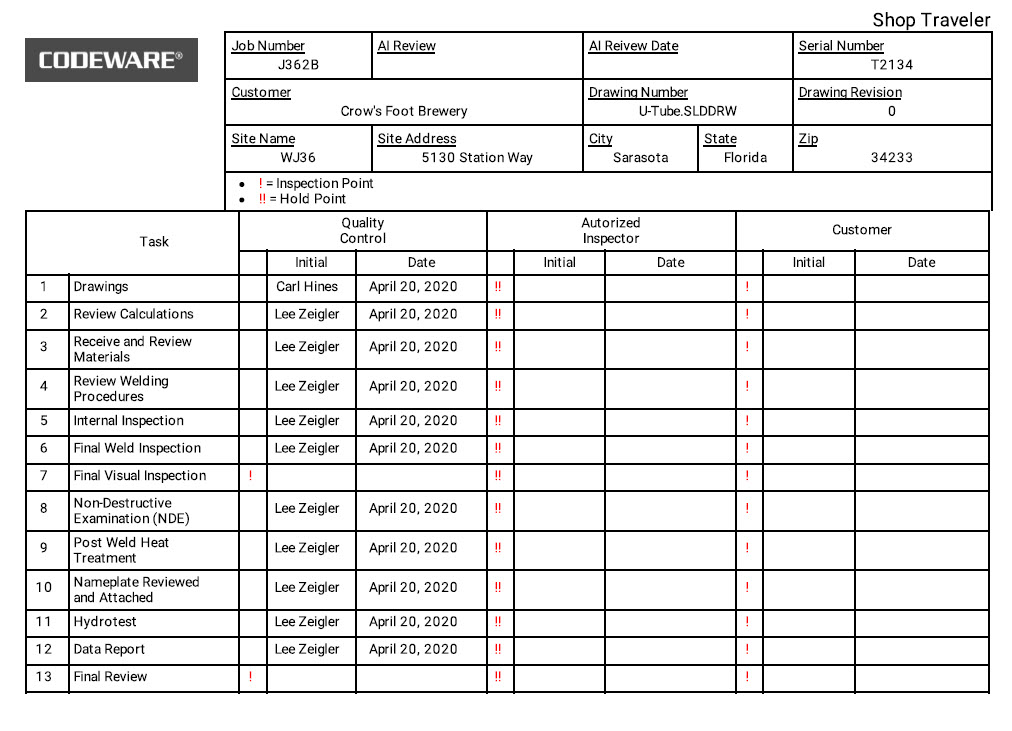

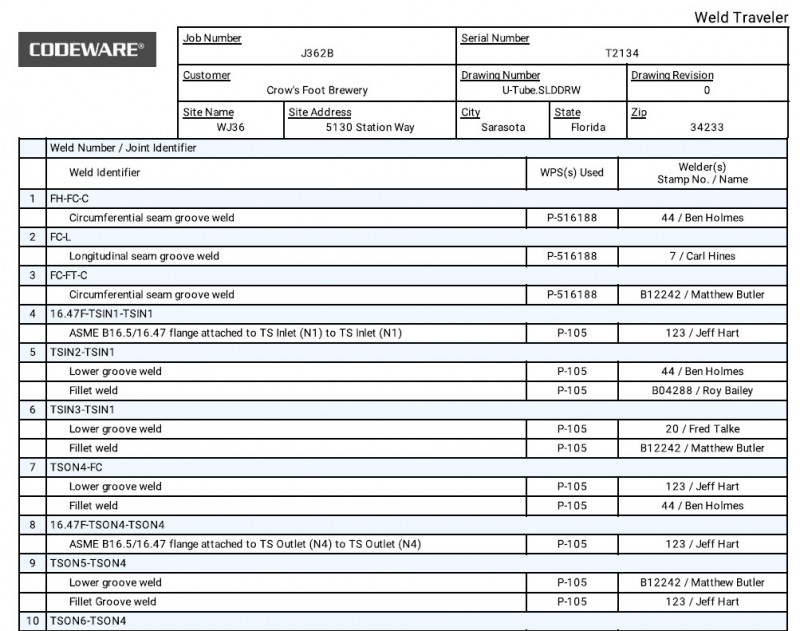

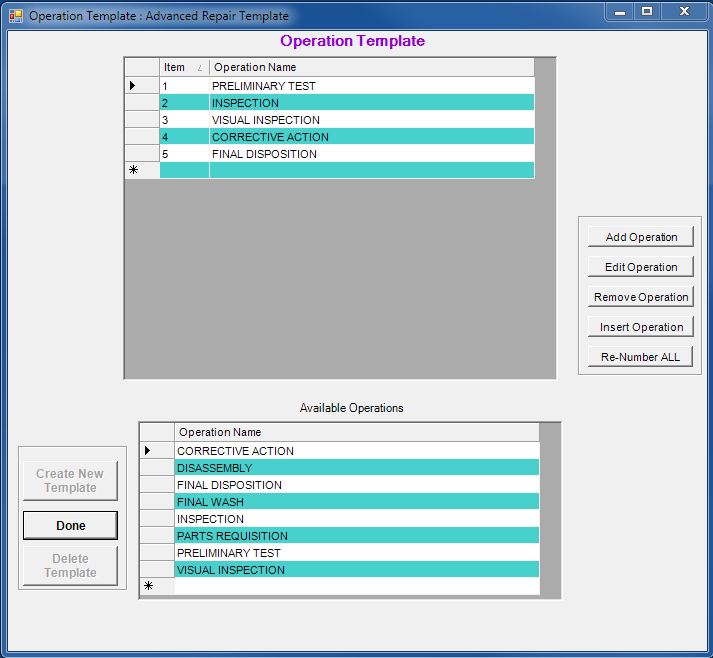

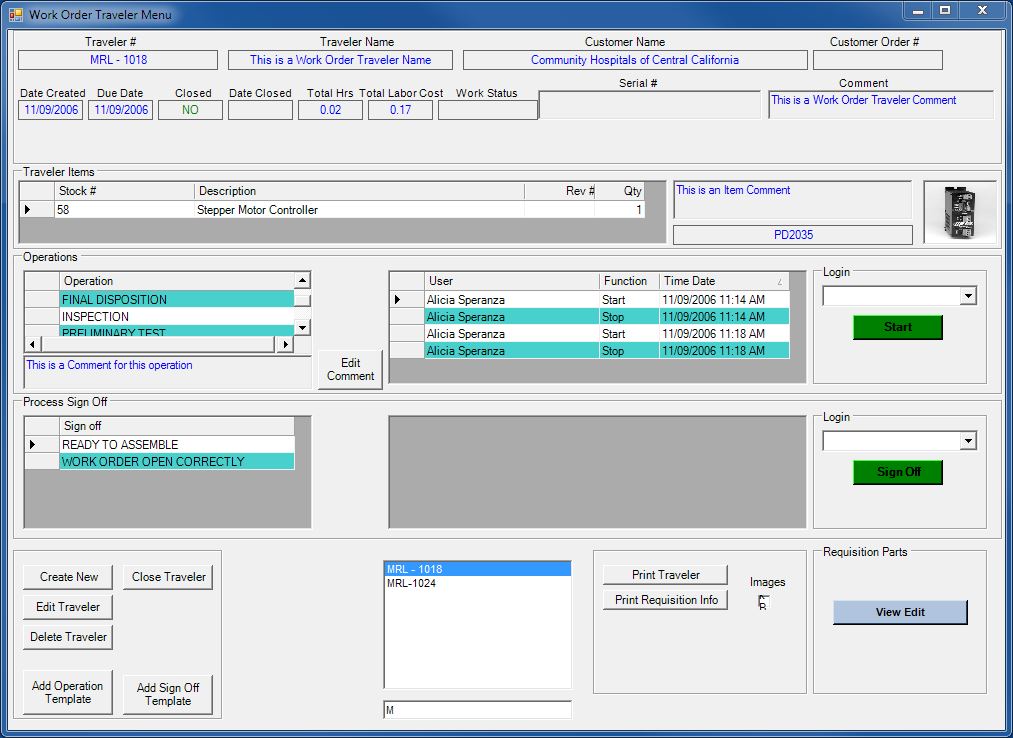

Manufacturing Traveler Template - Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. * quality assurance documentation, such as label reports with an actual label on the report * a form filled out by qa as final inspection of product, and one for final inspection of folder With them asking for your companies budget and other proprietary information you have a lot of work ahead to build something like that from scratch. Manufacturing engineering creates a traveler specific to a particular assembly or sub assembly. The template is designed as a two page form. * either a copy of the documents the product was made to or a traveler that lists the documents, revisions, and dates of manufacture. If i could receive a specific med device manufacturing build plan, that would be the best option. I just started and i am not yet familiar with the contract manufacturing business or the customer product. This agreement applies to all materials, components, subassemblies, and products manufactured for by supplier.</p> At the same time the technicians can access the traveler and are supplied with specific information, special requirements, material hazards, purchase order info, relevant blueprints/dwgs, etc. When creating a new traveler, use the most current form of the traveler template available on the network. However, i believe a generic build plan will be helpful as well (in the sense of a rough outline or format). These are documented and controlled thru revision level. This agreement applies to all materials, components, subassemblies, and products manufactured for by supplier.</p> At the same time the technicians can access the traveler and are supplied with specific information, special requirements, material hazards, purchase order info, relevant blueprints/dwgs, etc. I just started and i am not yet familiar with the contract manufacturing business or the customer product. The template is designed as a two page form. The purpose of this supplier quality agreement is to define the terms by which production activities will be established, controlled, and maintained for the manufacturing of products by (supplier). Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. This is why my question. This is why my question. Perhaps the above was not clear. It is a very effective system for controlling the flow of work and supplying staff with the information necessary to complete the job. These are documented and controlled thru revision level. The template is designed as a two page form. We control our manufacturing processes with process procedures, and capability studies. These are documented and controlled thru revision level. If i could receive a specific med device manufacturing build plan, that would be the best option. I just started and i am not yet familiar with the contract manufacturing business or the customer product. This agreement applies to all materials,. Customize it to accommodate the processes and information to be recorded. It is a very effective system for controlling the flow of work and supplying staff with the information necessary to complete the job. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the. If the rework is the result of an 'nc', you may want to include a reference traceable to that particular nc. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. Perhaps the above was not clear. However, i. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. The job travellers will have some job specific instructions on them but on the whole will simply describe the order in which things are done. We control our manufacturing. This agreement applies to all materials, components, subassemblies, and products manufactured for by supplier.</p> At the same time the technicians can access the traveler and are supplied with specific information, special requirements, material hazards, purchase order info, relevant blueprints/dwgs, etc. Why not consider using the same format as a normal traveler (renaming and making minor amendments to suit) because most. I just started and i am not yet familiar with the contract manufacturing business or the customer product. If i could receive a specific med device manufacturing build plan, that would be the best option. Perhaps the above was not clear. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general. If the rework is the result of an 'nc', you may want to include a reference traceable to that particular nc. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. With them asking for your companies budget and. We control our manufacturing processes with process procedures, and capability studies. These are documented and controlled thru revision level. The template is designed as a two page form. I just started and i am not yet familiar with the contract manufacturing business or the customer product. At the same time the technicians can access the traveler and are supplied with. Manufacturing engineering creates a traveler specific to a particular assembly or sub assembly. Why not consider using the same format as a normal traveler (renaming and making minor amendments to suit) because most items should be the same. The purpose of this supplier quality agreement is to define the terms by which production activities will be established, controlled, and maintained. * either a copy of the documents the product was made to or a traveler that lists the documents, revisions, and dates of manufacture. If i could receive a specific med device manufacturing build plan, that would be the best option. However, i believe a generic build plan will be helpful as well (in the sense of a rough outline or format). When creating a new traveler, use the most current form of the traveler template available on the network. Manufacturing plan template or example sounds to me that they are looking for a quality policy, scope & general process flow, ppap along with all the other subjects all linked together. It is a very effective system for controlling the flow of work and supplying staff with the information necessary to complete the job. Very few people have access to the edit function for the. Customize it to accommodate the processes and information to be recorded. I just started and i am not yet familiar with the contract manufacturing business or the customer product. The job travellers will have some job specific instructions on them but on the whole will simply describe the order in which things are done. If the rework is the result of an 'nc', you may want to include a reference traceable to that particular nc. These are documented and controlled thru revision level. This agreement applies to all materials, components, subassemblies, and products manufactured for by supplier.</p> Manufacturing engineering creates a traveler specific to a particular assembly or sub assembly. Why not consider using the same format as a normal traveler (renaming and making minor amendments to suit) because most items should be the same. The purpose of this supplier quality agreement is to define the terms by which production activities will be established, controlled, and maintained for the manufacturing of products by (supplier).Traveler Sample Business Process Production And Manufacturing

Production Traveler Template

Production Traveler Template

Production Traveler Template

Manufacturing Job Traveler Template Excel Master of

Machine Shop Traveler Template

Manufacturing Traveler Operation Template

Manufacturing Traveler Template

Manufacturing Job Traveler Template Excel 20202021 Fill and Sign

Manufacturing Job Traveler Template Excel Master of

We Control Our Manufacturing Processes With Process Procedures, And Capability Studies.

This Is Why My Question.

With Them Asking For Your Companies Budget And Other Proprietary Information You Have A Lot Of Work Ahead To Build Something Like That From Scratch.

At The Same Time The Technicians Can Access The Traveler And Are Supplied With Specific Information, Special Requirements, Material Hazards, Purchase Order Info, Relevant Blueprints/Dwgs, Etc.

Related Post: