Loto Procedure Template

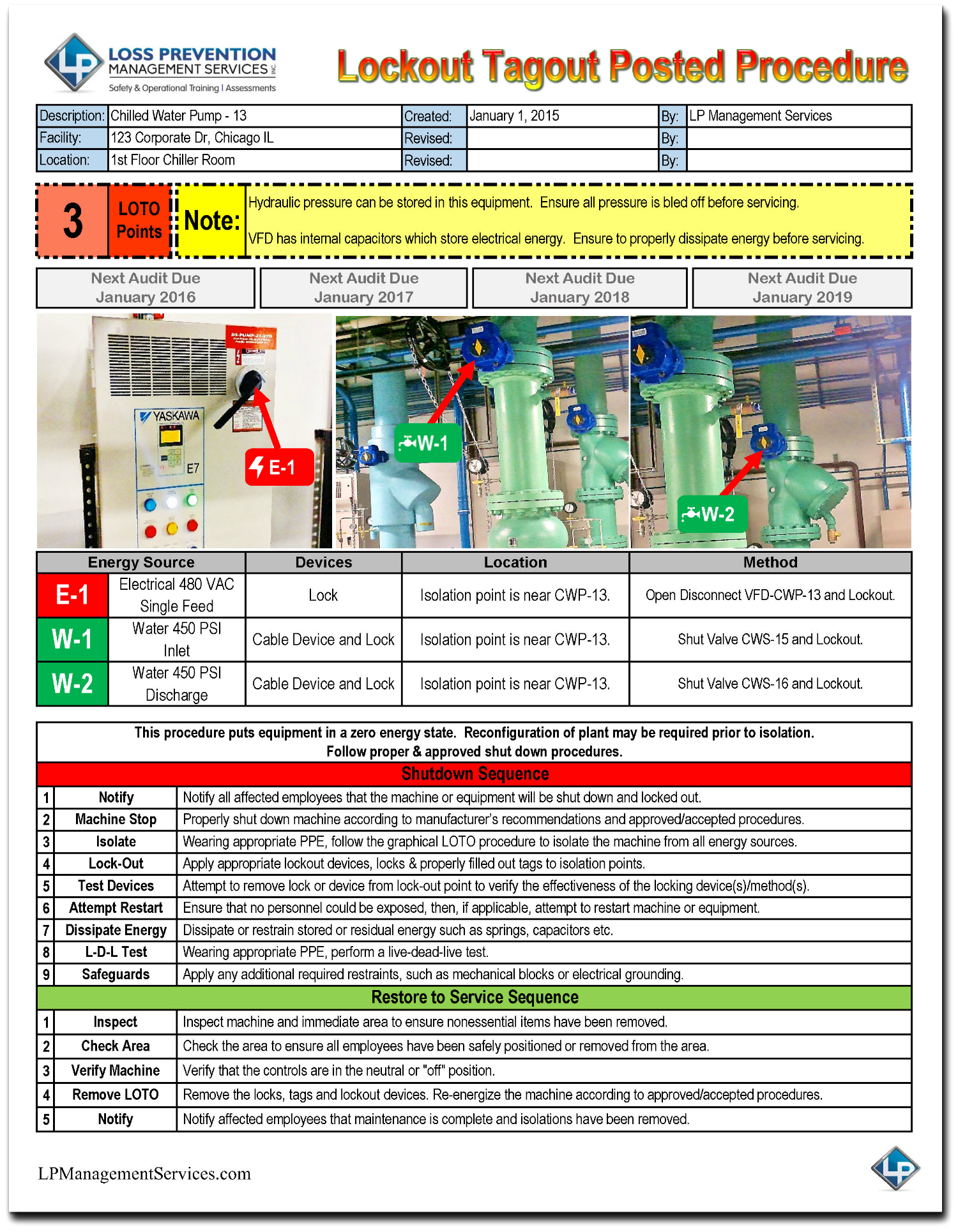

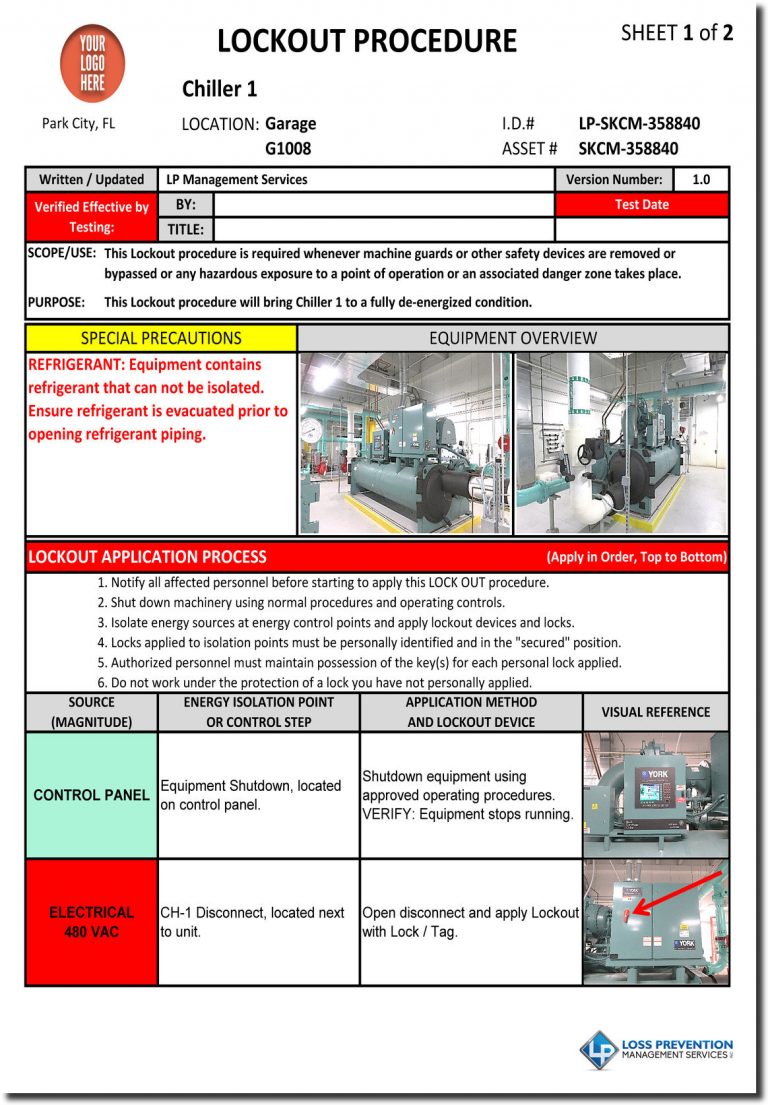

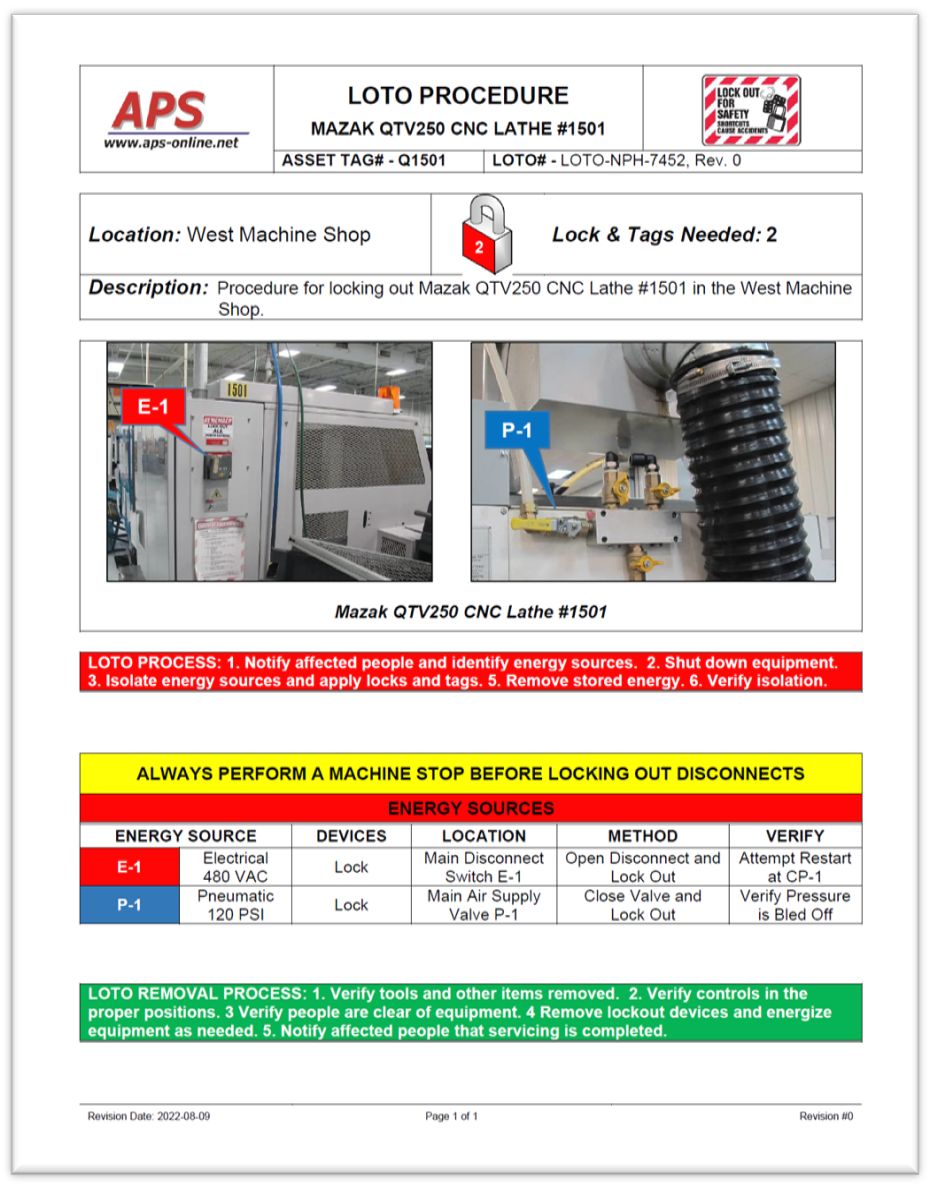

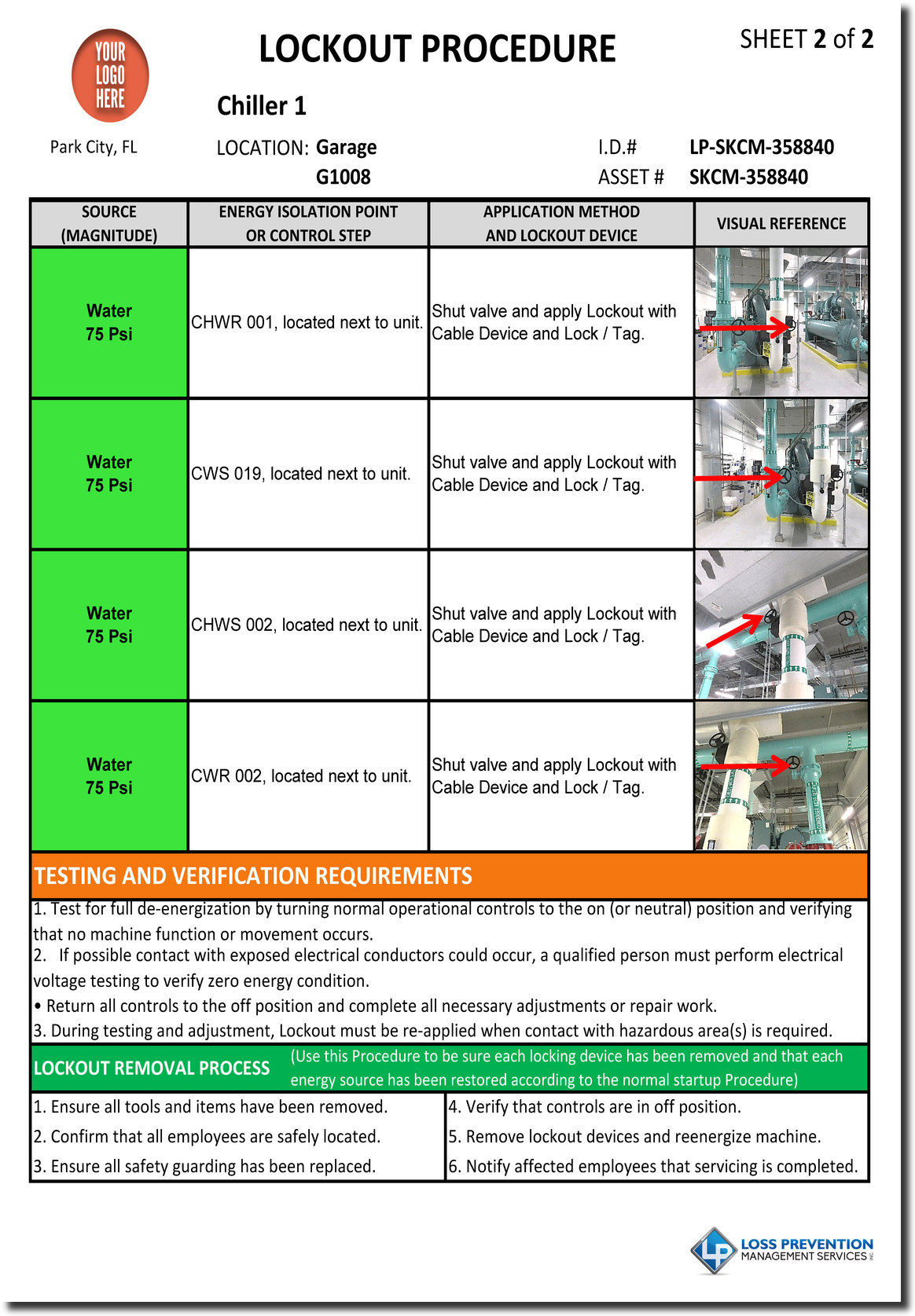

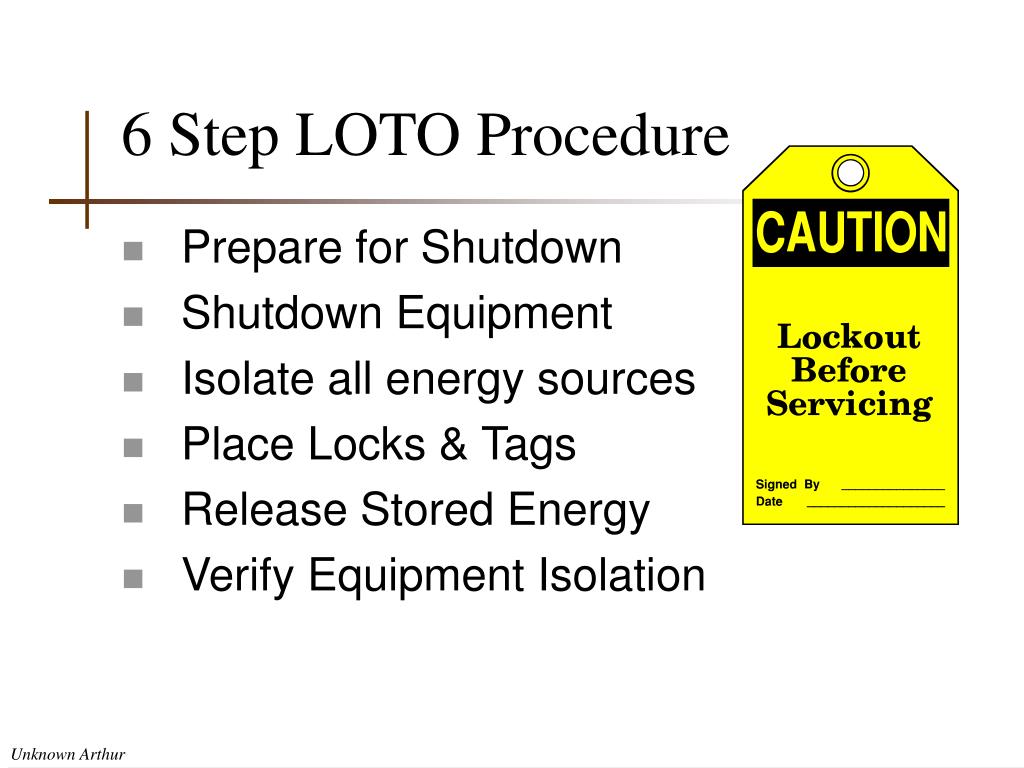

Loto Procedure Template - Lockout/tagout/tryout procedures (commonly known as “loto”) are typically designed to ensure that qualified persons isolate all energy sources before electrical work can be performed. Existing loto procedures are acceptable until fy16, after which they must be converted to the standard format in the lockout/tagout (loto) procedure template. Loto will follow the specific instructions for each piece of equipment/machinery to identify, disconnect, isolate, lock out and verify the lock out of the appropriate energy sources. If employers wish, they may use these forms to evaluate their workplace equipment, then customize the lockout/tagout model program, which is available on the cal/osha publications webpage. All berkeley lab loto procedures must follow the standard format included in the lockout/tagout (loto) procedure template. Review the machine or equipment specific loto procedure to locate and identify all energy isolating devices. Notify all affected employees that a loto procedure will be utilized and why. Prior to entry into any grain bin or grain storage structure. Prior to entry into any area or structure where operating equipment would pose a hazard. Before servicing or maintenance of equipment. Cal/osha provides the sample forms included in this publication to help employers establish hazardous energy control procedures required by title 8 section 3314. Prior to entry into any area or structure where operating equipment would pose a hazard. Conduct a job safety analysis for repair and maintenance processes. All energy sources for each piece of equipment will be shut down and the energy source Before servicing or maintenance of equipment. Review the machine or equipment specific loto procedure to locate and identify all energy isolating devices. Existing loto procedures are acceptable until fy16, after which they must be converted to the standard format in the lockout/tagout (loto) procedure template. Prior to entry into any grain bin or grain storage structure. Provide annual training to employees affected by lockout and tagout procedures. All berkeley lab loto procedures must follow the standard format included in the lockout/tagout (loto) procedure template. Prior to entry into any grain bin or grain storage structure. Review the machine or equipment specific loto procedure to locate and identify all energy isolating devices. Notify all affected employees that a loto procedure will be utilized and why. Inspect energy control procedures and practices at least annually to ensure that general and. Prior to entry into any area. This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment. The procedures must include the following information: More than one hazardous energy source and/ or means of disconnect may be present. Review the machine or equipment specific loto procedure to locate and identify all energy isolating devices.. Lockout/tagout/tryout procedures (commonly known as “loto”) are typically designed to ensure that qualified persons isolate all energy sources before electrical work can be performed. Inspect energy control procedures and practices at least annually to ensure that general and. Each loto will follow the general process listed below. Provide annual training to employees affected by lockout and tagout procedures. Conduct a. Loto will follow the specific instructions for each piece of equipment/machinery to identify, disconnect, isolate, lock out and verify the lock out of the appropriate energy sources. More than one hazardous energy source and/ or means of disconnect may be present. Cal/osha provides the sample forms included in this publication to help employers establish hazardous energy control procedures required by. Before servicing or maintenance of equipment. Inspect energy control procedures and practices at least annually to ensure that general and. All berkeley lab loto procedures must follow the standard format included in the lockout/tagout (loto) procedure template. Prior to entry into any area or structure where operating equipment would pose a hazard. This procedure establishes the minimum requirements for the. Conduct a job safety analysis for repair and maintenance processes. Notify all affected employees that a loto procedure will be utilized and why. Inspect energy control procedures and practices at least annually to ensure that general and. If employers wish, they may use these forms to evaluate their workplace equipment, then customize the lockout/tagout model program, which is available on. Notify all affected employees that a loto procedure will be utilized and why. Each loto will follow the general process listed below. Loto will follow the specific instructions for each piece of equipment/machinery to identify, disconnect, isolate, lock out and verify the lock out of the appropriate energy sources. Lockout/tagout/tryout procedures (commonly known as “loto”) are typically designed to ensure. Before servicing or maintenance of equipment. Inspect energy control procedures and practices at least annually to ensure that general and. More than one hazardous energy source and/ or means of disconnect may be present. Existing loto procedures are acceptable until fy16, after which they must be converted to the standard format in the lockout/tagout (loto) procedure template. Conduct a job. Inspect energy control procedures and practices at least annually to ensure that general and. All energy sources for each piece of equipment will be shut down and the energy source If employers wish, they may use these forms to evaluate their workplace equipment, then customize the lockout/tagout model program, which is available on the cal/osha publications webpage. Prior to entry. This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment. Cal/osha provides the sample forms included in this publication to help employers establish hazardous energy control procedures required by title 8 section 3314. Existing loto procedures are acceptable until fy16, after which they must be converted to. All berkeley lab loto procedures must follow the standard format included in the lockout/tagout (loto) procedure template. This procedure establishes the minimum requirements for the lockout of energy isolating devices whenever maintenance or servicing is done on machines or equipment. Before servicing or maintenance of equipment. Prior to entry into any grain bin or grain storage structure. Prior to entry into any area or structure where operating equipment would pose a hazard. Notify all affected employees that a loto procedure will be utilized and why. Review the machine or equipment specific loto procedure to locate and identify all energy isolating devices. Lockout/tagout/tryout procedures (commonly known as “loto”) are typically designed to ensure that qualified persons isolate all energy sources before electrical work can be performed. Conduct a job safety analysis for repair and maintenance processes. Loto will follow the specific instructions for each piece of equipment/machinery to identify, disconnect, isolate, lock out and verify the lock out of the appropriate energy sources. If employers wish, they may use these forms to evaluate their workplace equipment, then customize the lockout/tagout model program, which is available on the cal/osha publications webpage. Cal/osha provides the sample forms included in this publication to help employers establish hazardous energy control procedures required by title 8 section 3314. The procedures must include the following information: Provide annual training to employees affected by lockout and tagout procedures. More than one hazardous energy source and/ or means of disconnect may be present.Lockout Tagout Procedure Development LP Management Services

What is a Lockout Tagout LOTO Procedure Brady Best Practices

Lockout Tagout Template Excel, Explore loto training lockout tagout

Lockout Tagout Procedures Development LP Management Services

LockoutTagout (LOTO) Procedure Writing Services APS

Lock Out Tag Out Procedure Checklist (2024) (With Template)

Lockout Tagout Procedures Development LP Management Services

Free Lockout Tagout Procedure Template Word Ben Version 2 Page Loto

PPT LOCKOUT TAGOUT PowerPoint Presentation, free download ID1782302

LOTO implementation is important to lock out, tag out power sources and

Inspect Energy Control Procedures And Practices At Least Annually To Ensure That General And.

All Energy Sources For Each Piece Of Equipment Will Be Shut Down And The Energy Source

Existing Loto Procedures Are Acceptable Until Fy16, After Which They Must Be Converted To The Standard Format In The Lockout/Tagout (Loto) Procedure Template.

Each Loto Will Follow The General Process Listed Below.

Related Post: